Why Does the Concrete Mixer Truck Keep Rotating?

2022-06-06 16:26:30

We all know that concrete is a material that must be used in the process of building houses and roads. Concrete is composed of water, sand, gravel and cement.

However, in many construction sites, due to the limitations of conditions, these materials cannot be used to make concrete on the spot, but the concrete needs to be made at a professional site, and then the concrete is transported to the site with a special truck, which is called

concrete mixer truck.

In fact, we are familiar with concrete mixer trucks because we can often see them on the road or on construction sites. At the same time, we may have many questions, such as why the tank keeps rotating and what is the internal structure of the tank. This article will talk about these in detail.

What is concrete mixer truck?

Concrete mixer truck is a special vehicle for transporting concrete. Because there is always a rotating mixing tank on the truck when transporting, it is also called a snail truck.

The concrete manufacturing plant, that is, the

mixing station, will directly load the finished concrete into the concrete mixer tank. The concrete mixer truck will transport it to the construction site, and then pour the concrete out of the tank to directly pour the road or wall.

Concrete mixer trucks are also one of the most widely used and frequently used construction equipment in construction projects today.

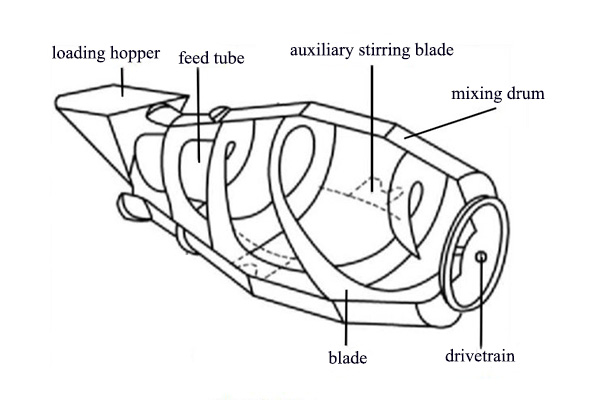

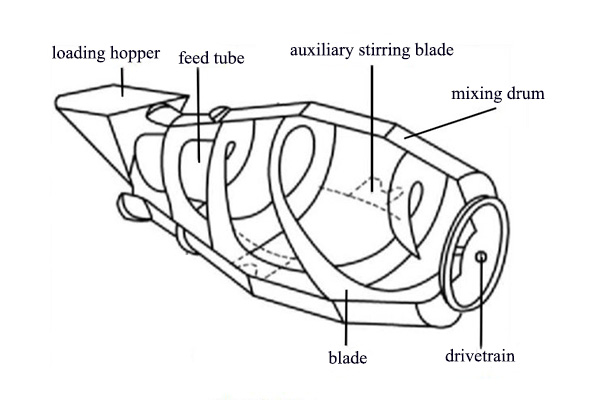

Structure of concrete mixer tank

The outer shell of the tank is made of wear-resistant steel. In order to automatically load and unload concrete, there are also special-shaped rotating blades welded inside. When rotating, the concrete will move in the direction of the rotation of the blades. In the process of continuous rotation and flipping, all ingredients can be stirred and mixed thoroughly.

During the loading and transportation process, the tank body rotates in a clockwise direction, and the concrete will move inward with the blade, While during the unloading process, the tank body will reverse, and the concrete will be discharged outward along the blade.

The rotation of the tank is completed by the hydraulic drive system on the truck. Usually, the hydraulic pump is driven by the power take-off shaft on the truck to drive the mixing tank to rotate.

Why does the concrete mixer tank keep rotating?

The concrete is composed of stone, sand, cement and water, if the concrete mixer tank does not rotate during transportation and is constantly bumped, the stone will sink to the bottom, the sand will be in the middle, and the cement and water will be on the top. There will be agglomeration when at the destination, which is also what we often call the “stuffy tank”. About the stuffy tank, you can read the article

Concrete Mixer Truck: Why Would We rather Dump the Concrete than Stuff It. Therefore, rotating prevents the concrete from solidification and delamination, and also allows the concrete to be mixed more uniformly.

We can often see various traffic accidents about concrete mixer trucks in various reports, which also caused a lot of casualties. The main reasons are following: The entire chassis of the concrete mixer truck is very high, so there will be a lot of blind spots for the drivers, especially when turning.

In addition, the speed of concrete mixer trucks is generally fast, and the braking distance will be longer due to the body and heavy concrete, which are the reasons for the frequent occurrence of accidents. Therefore, it is still necessary to stay away from the concrete mixer as much as possible to keep safe.