4 Major Advantages and Disadvantages of Concrete Mixer Trucks

2022-04-15 17:22:54

Concrete mixer trucks play a linking role in the entire transportation link, and play a connecting role in the entire transportation network.

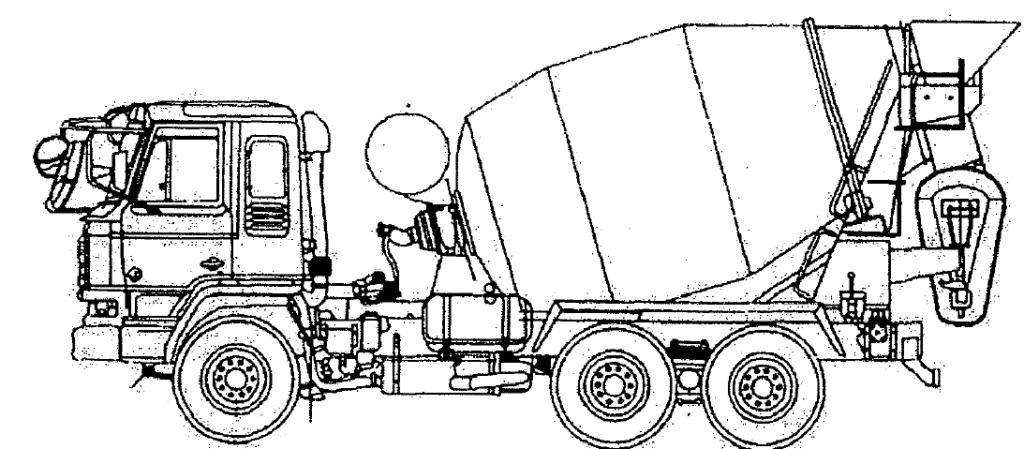

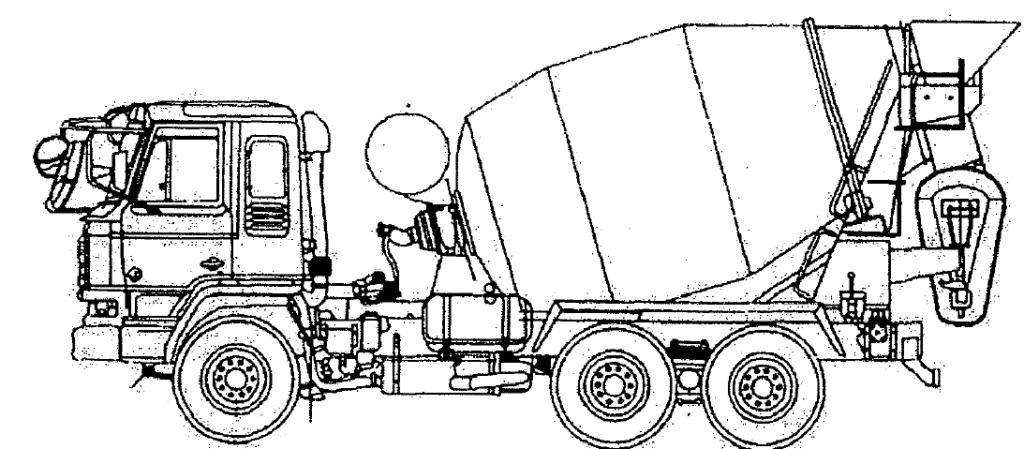

Concrete mixer trucks are widely used in construction projects. It has the ability to automatically load and unload concrete mixtures, especially in the process of transportation, which can agitate the concrete evenly and continuously, and can also maintain the water content of the concrete. The following is a schematic diagram of the structure of the concrete mixer truck.

Concrete mixer truck is one of the important links in the concrete conveying process. It is used in conjunction with the concrete mixing station and the concrete pump truck to completely mechanize, automate and intelligentize the preparation, transportation and molding of concrete. Concrete mixer trucks play a linking role in the entire transportation link, and play a connecting role in the entire transportation network. This not only improves the construction efficiency and quality, but also helps to maintain the environment and promote the harmonious development of society for urban construction.

Judging from the working conditions and structural characteristics of the concrete mixer truck, it has the characteristics of strong professionalism, strong service, poor balance, strong timeliness, strong transportation and limited transportation time and distance.

PROFESSIONAL

As can be seen from the name of the concrete mixer truck, this kind of mechanical equipment is mainly used for concrete manufacturing and transportation. The agitation and transportation of ready-mixed concrete is mainly to transport the finished concrete mixed by the concrete mixing station. During the transportation, the rotation speed of the mixing drum must be well controlled at a low speed of about 3 rpm, and the concrete is continuously turned and stirred by the blades in the mixing drum to prevent segregation or compaction caused by static, and ensure the quality of concrete transported to the construction site. Although the transportation distance increases, the distance and time cannot be too long and cannot exceed the coagulation time of the concrete. The time is still restricted by many factors such as the quality of the concrete and the environment. So strictly speaking, under different seasons and times, the shipping time varies.

The transportation of the mix is different from that of the ready-mix. The mix is not a finished concrete, it is a semi-finished product. Therefore, the mixing speed of the mixing drum during transportation is much faster than that of the ready-mixed material. Generally, the speed is controlled between eight to ten revolutions per minute according to the proportion of the concrete mixture. In order to save time, the mixture can also be mixed into finished concrete during transportation, which requires the addition of corresponding devices such as water tanks. This kind of mixing during transportation can increase a lot of transportation distance and prolong concrete condensation. Therefore, it is a good choice for long-distance transportation.

Although in order to increase the transportation distance and prolong the transportation time, the use of mixing materials to be mixed into finished materials during transportation can save fixed investment and improve relative productivity. However, the disadvantages of this method are also obvious. It is difficult to obtain finished concrete of good quality, mainly due to the limitation of equipment, which cannot obtain uniform concrete.

For construction with strict requirements, it is better to use ready-mixed concrete agitation and transportation, so the concrete mixer trucks we see are mostly ready-mixed concrete mixer trucks on the road.

STRONG SERVICE, POOR BALANCE

We adopt the mode of industrialized production of concrete and can transport concrete according to the form of modern logistics, which can achieve a real all-round and full-time customer-oriented service. Everything is produced and transported according to the user's project progress and concrete usage standards, which can save time ,labor, material and financial resources,

It can also promote the development of this business. However, the nature of concrete determines the time of preparation and transportation. It can neither be advanced nor delayed. Users are always on call. Otherwise, it will not only cause waste of ready-mixed concrete, but also have a negative impact on the reputation of the fleet.

TIME-SENSITIVE

Due to the characteristics of the above-mentioned ready-mixed concrete itself, the concrete must be delivered to the work site within two hours after production, which is very short for special concrete. Moreover, the pouring of concrete is continuous without any pause in the middle, which reduces the bleeding rate of concrete, otherwise it will have a great impact on the quality of the project.

SHORT TRANSPORT DISTANCE

The characteristics of strong timeliness create restrictions on the transportation distance. According to traffic regulations and vehicle conditions, the reasonable distance is generally controlled within 20 kilometers.

The above are the four major advantages and disadvantages of concrete mixer trucks. If you are interested in concrete mixer trucks, you can contact

Zhengzhou Talenet Tech co,. ltd, we have second-hand concrete mixer trucks, which can save your expenses and make you satisfied.